Have you ever wondered how factories make wooden climber that are fun and engaging and meet international safety standards for young children? What steps do manufacturers take to ensure quality, function, and child-friendliness?

Wooden climbers produced in professional factories are carefully engineered using safe materials and stable structures. They help children develop strength, coordination, and confidence through active play. These climbers are widely used in kindergartens, daycares, early learning centers and at home, providing age-appropriate movement opportunities that support healthy physical development and social interaction.

In this article, we’ll walk you through how factories make wooden climbers—from selecting high-quality wood and crafting stable designs to finishing, polishing, and safety testing. If you’re sourcing for a preschool, daycare, or early education project, understanding this process can help you make more informed purchasing decisions. Let’s dive into the details.

Wooden Climbers Are Important for Kids

Wooden climbers are becoming a staple in many early childhood educational settings, from daycares and preschools to Montessori classrooms. But why are they so crucial for children? These simple yet effective play structures offer far more than just a fun way to pass the time—they are a vital tool in child development. We explore why incorporating them into play areas is crucial for young learners.

The Physical Benefits of Wooden Climbers

One of the most significant advantages of wooden climbers is their impact on physical development. Physical activity is an essential part of growth for children, and these climbers provide the perfect space for active play. Here’s how:

Gross Motor Skills Development

Wooden climbers engage children in various physical movements such as climbing, balancing, crawling, and jumping. These movements are crucial for developing gross motor skills—skills that involve large muscle groups and help children achieve coordination and balance. Activities like climbing up a ramp or balancing on a beam require a child to engage their arms, legs, and core muscles, contributing to their physical strength and stability.

Strengthening of Muscles and Bones

As children push, pull, and climb, their muscles are strengthened. The weight-bearing activities that wooden climbers promote help build bone density and muscle mass. This is especially important when bone growth and muscle development peak in the early years. The physical exertion required to conquer a wooden climber helps lay the foundation for an active lifestyle as the child grows.

Improved Coordination and Balance

The design of wooden climbers often includes challenging elements such as ladders, ramps, and platforms. These features require children to maintain balance and adjust their movements, enhancing their spatial awareness and motor coordination. These skills are essential for activities later in life, such as sports, dancing, or even walking on uneven ground.

Cognitive and Emotional Development through Play

While wooden climbers are primarily used for physical play, they contribute significantly to a child’s cognitive and emotional development.

Problem Solving and Risk Assessment

Climbing is not only a physical activity but also a cognitive one. As children climb, they must think critically about approaching each obstacle. Is the ladder too steep? Can I reach that next step? These problem-solving tasks help develop cognitive skills such as spatial awareness, decision-making, and risk assessment. Children learn to navigate their environment, test their limits, and determine the safest routes to success.

Confidence and Self-Esteem

Completing a challenge like climbing to the top of a wooden climber gives children a sense of accomplishment and boosts their self-esteem. Every time a child conquers a new height or balance challenge, they build confidence in their abilities. This sense of achievement motivates children to try new things and fosters resilience, as they learn that perseverance leads to success.

Emotional Regulation and Self-Control

Children engage in active play on wooden climbers and practice emotional regulation. Climbing can be frustrating when a child struggles to reach the top or loses balance. However, with guidance and support, they learn how to manage their frustration, calm themselves, and try again. This emotional resilience is essential for emotional growth, helping children learn how to handle setbacks in life.

Social Skills and Cooperation

Beyond individual development, wooden climbers also serve as a platform for social interaction, allowing children to engage with their peers in a collaborative environment.

Sharing and Turn-Taking

In group settings, children often have to wait their turn to climb or use different features of the wooden climber. This provides an opportunity for them to practice patience, turn-taking, and sharing—valuable social skills that they will carry into adulthood. These interactions help children understand social norms and how to navigate group dynamics, making them better equipped for group work in school and life.

Encouraging Cooperation and Communication

As children climb together, they often work together to solve problems or figure out how to use the equipment. Whether it’s helping a friend reach the next step or encouraging each other to complete the climb, children learn the importance of cooperation, teamwork, and effective communication. These interactions promote empathy and understanding, helping children develop the social skills they need to build relationships with others.

Inclusive Play

Wooden climbers can also be designed with inclusivity in mind, accommodating children of different abilities. For example, low-to-the-ground platforms, wide spaces, or handrails can make the structure accessible for children with disabilities or those who are still developing their motor skills. This inclusivity ensures that all children, regardless of their physical abilities, can benefit from the developmentally enriching play that wooden climbers offer.

Why Make Wooden Climbers in a Factory Setting?

Durability That Withstands Daily Use

Factories produce wooden climbers using precision tools and high-grade materials. This ensures that every product can endure years of use by energetic children. Components are engineered for strength, with layered wood and reinforced joints that resist impact, weight, and environmental changes. Compared to DIY or low-volume workshop production, factory output is significantly more resilient, consistent, and suited to institutional use. The manufacturing process is standardized with quality checks built into every phase, reducing unit variability.

Unmatched Safety and Consistency

Make wooden climbers in a controlled manufacturing environment guarantees compliance with strict international safety standards. Automated machinery reduces human error, and each climber undergoes a series of safety inspections and tests. Unlike handcrafted alternatives, factory climbers are reliable and replicable across multiple orders. Child-friendly features such as rounded corners, non-toxic finishes, and reinforced joins are not optional but essential.

Materials Matter: Choosing the Right Wood

Selecting Safe and Sustainable Timber

To make wooden climbers safe for kids, factories choose timber that’s not only strong but also smooth and splinter-free. Common options include:

- Solid pine for cost-effectiveness and versatility

- Birch plywood for surface consistency and strength

- Laminated veneer lumber (LVL) for added stability and moisture resistance

Wood is typically FSC-certified and responsibly sourced, aligning with green procurement goals. It is selected not only for mechanical performance but also for surface smoothness, odor neutrality, and chemical safety. Factories often maintain long-term partnerships with certified sawmills and suppliers.

Moisture Content Control

Before production begins, every plank is kiln-dried to achieve a moisture content below 12%. This step is critical in preventing warping, cracking, or mold development later. Moisture meters are used throughout the process to ensure optimal wood condition. Boards are tested at various stages: before processing, during cutting, and after coating, guaranteeing stable and durable final products.

The Design Process: Where Safety Meets Creativity

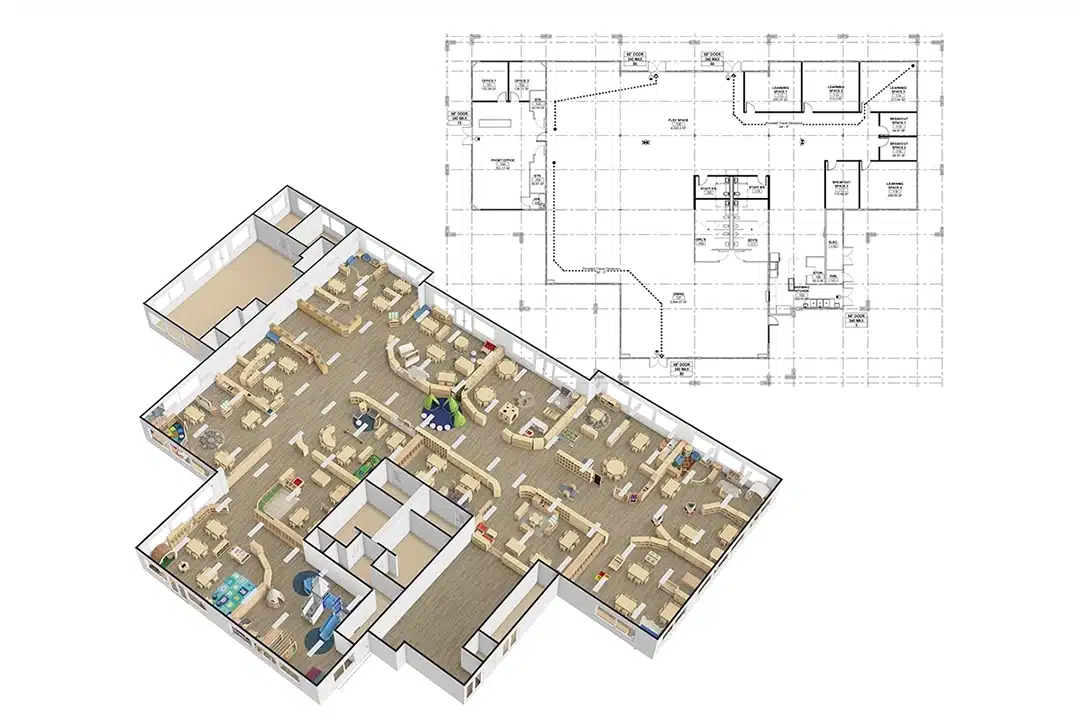

CAD Modeling and 3D Simulation

To make wooden climbers that are safe and functional, factories begin with digital models. CAD (Computer-Aided Design) software helps engineers visualize the entire structure in 3D, identify stress points, and test load distribution. Engineers can simulate a climber’s performance under different weights and movement types, optimizing frame angles and support joints. This digital prototyping ensures fewer material errors and greater long-term durability.

Child-Centered Design Principles

Designs are tailored to children’s motor abilities by age. For example:

- Toddlers: low platforms, short ramps, wide handles

- Preschoolers: mid-level climbing panels, balance beams, integrated slides

Designers also integrate elements like crawling spaces, bridges, tunnels, and entry points that support creative and cooperative play. Feedback from early childhood educators is often incorporated into the process, resulting in climbers that don’t just look engaging but function as educational tools.

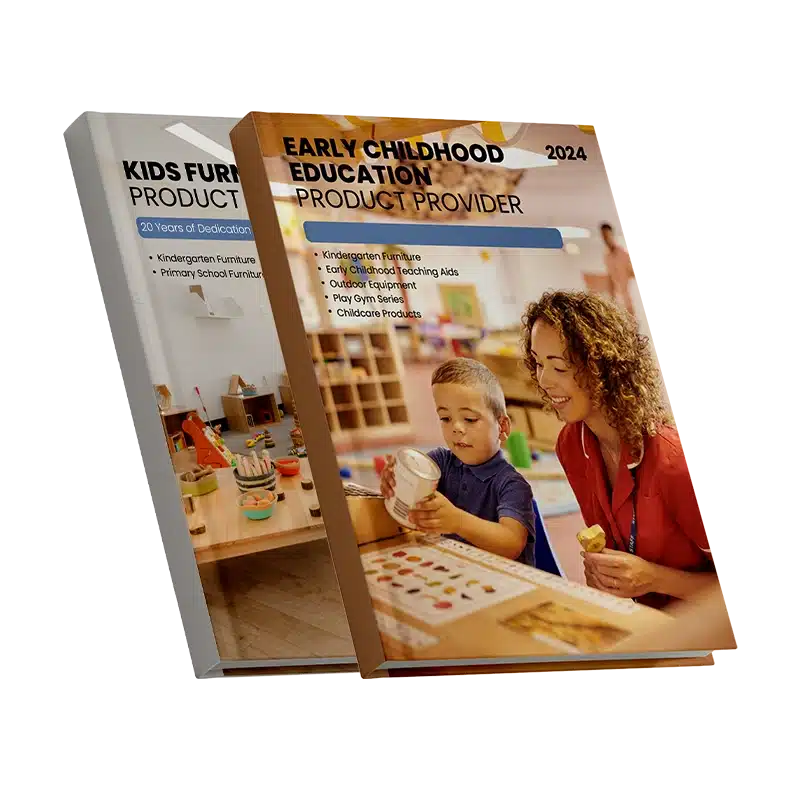

Xiha Montessori to Make Wooden Climber and Preshcool Furniture

At Xiha Montessori, we don’t just make wooden climber products—we provide a complete one-stop solution for your preschool furniture needs, from material selection to shipping. We use various high-quality, eco-friendly board types, including birch plywood, beechwood, and laminated MDF. All materials are carefully selected and comply with EN71, ASTM, and other safety certifications to ensure child safety and durability.

Our clients—kindergarten owners, education groups, and wholesalers—value convenience and reliability. That’s why we’ve built a one-stop procurement system. From the moment you request a quote, our team handles design drafts, material confirmation, product manufacturing, packaging, documentation, and shipping logistics in one smooth workflow.

Our make wooden climber is polished to perfection, sanded with child-safe finishes, and tested for weight-bearing safety. Whether it’s a climbing triangle, slide, arch, or balance ramp—we make sure it’s both educational and physically supportive for preschool-age children.

Do you need your school logo on the climber? Do you prefer natural wood tones or bright colors? Do you want different height or angle adjustments for different age groups? We offer custom-built wooden climbers tailored to your curriculum and student needs. Whether Montessori, Reggio, or Waldorf, we get it.

How to Make Wooden Climber?

Step 1: Wood Cutting with CNC Routers

Most factories use CNC (Computer Numerical Control) routers to make wooden climber components accurately and efficiently. These machines follow programmed paths to cut wood panels into precise shapes and sizes. The process begins by feeding pre-dried, pre-checked wood into the CNC machine. Each panel is scanned for grain orientation and defect spots. The machine then performs:

- Outline cuts for frames and panels

- Slots for joints

- Holes for screws and dowels

- Inlays for optional branding

Benefits of CNC cutting include zero deviation between units, reduced material waste, and enhanced productivity. CNC routers allow the simultaneous cutting of multiple panels, enabling mass production without losing accuracy.

Step 2: Edge Smoothing and Sanding

After cutting, each piece moves to edge smoothing and sanding. Factories use a combination of belt sanders, orbital sanders, and hand sanding tools. Smooth surfaces are essential—not just for tactile comfort but to prevent splinters and ensure safe contact for small hands and feet.

Sanding usually happens in three stages:

- Rough sanding to remove fibers and minor machine marks.

- Medium sanding to smooth curves and edges.

- Finish sanding for ultra-fine polish before coating.

Additional sanding may be done manually on corners, curved rails, and intricate designs to achieve a safe and appealing finish. Attention to detail in this phase is what distinguishes professional-grade climbers.

Step 3: Structural Reinforcement

Not all wood is load-bearing in the same way. To make wooden climbers structurally reliable, factories reinforce key areas using methods such as:

- Glued laminated beams (glulam) for large spans

- Hidden metal brackets or dowels for joint support

- Double-thick layers at weight-bearing zones

Reinforcement is essential in climbing base, cross-supports, and ladder rails. These parts are subjected to repeated stress, and without reinforcement, even quality wood can fail over time. Some manufacturers also use corner blocks and screw-through joints to lock multi-directional forces.

Step 4: Drilling and Pre-Assembly

Each component is then drilled for assembly. Holes must be perfectly aligned to allow simple, stable construction on-site. Factories may use jigs and templates to ensure uniformity. At this point, some manufacturers perform pre-assembly:

- Parts are joined temporarily

- Fit and alignment are verified

- Movement and torque are tested

This dry-fit process allows detection of any discrepancies in cut, angle, or hole depth before the product reaches the customer.

Step 5: Surface Coating and Child-Safe Finishing

To make wooden climber products visually appealing and safe for children, surface treatment plays a key role. This phase combines aesthetics, durability, and compliance with chemical safety standards.

Water-Based and Non-Toxic Finishes

Factories use child-safe paints and finishes to seal and protect the wood. These may include:

- Water-based lacquer: Low VOC and fast-drying

- Plant-based oils: Popular for Montessori-style products, enhancing natural grain

- UV-resistant clear coats: For outdoor climbers, protecting from the sun and rain

Each finish is applied in a dust-controlled environment to prevent contamination. Most factories apply 2–3 layers, sanding lightly between coats to ensure a smooth and even surface.

Color Customization and Visual Branding

Many clients opt for customized colors in addition to natural finishes. Factory systems allow for batch-matching of colors to ensure consistency across orders. Logos and slogans can be screen-printed or laser-engraved. This branding adds a professional touch, especially for international school chains.

Step 6: Safety Testing and Quality Control

Safety is central to how manufacturers make wooden climber equipment. Each product must pass rigorous testing before leaving the factory.

Structural Safety Testing

- Load-bearing simulations: Weights are applied to ensure stability

- Impact resistance checks: Especially for edges and connecting joints

- Tipping analysis: To ensure climbers won’t topple during aggressive play

Certification and Compliance

Most top-tier factories comply with certifications such as:

- EN71 (Europe)

- ASTM F963 and CPC (USA)

- ISO 9001 for quality management

Step 7: Packaging and International Shipping

Once production is complete, every wooden climber is carefully packaged for global delivery.

Flat-Pack

To reduce shipping volume and cost, climbers are packed in flat, disassembled form. Each package includes:

- Labeled components with part numbers

- Hardware kit with screws, Allen keys, etc.

- Color-coded instructions in multiple languages

Protective Materials

Soft foam padding, edge guards, and shrink-wrap ensure the product arrives pristine. Outer cartons are labeled with moisture-proof stickers and handling instructions.

Logistics and Global Distribution

Factories coordinate with freight forwarders to deliver to ports, warehouses, or even door-to-door. Clients can choose from:

- EXW or FOB shipping terms

- Air freight for urgent small-volume orders

- Sea freight with customs clearance support

The following is the finished product of our make wooden climber

The Pikler Triangle is a wooden climbing structure that promotes physical development and independence in children. Its smooth edges and non-toxic finishes ensure safety. Suitable for children aged 6 months to 6 years, it encourages balance, coordination, and creative play. Its adjustable height and compatibility with ramps provide versatility for growing children, making it a great addition to any learning environment.

The Wooden Climbing Arch is a versatile play structure that enhances children’s balance, coordination, and motor skills. Made from durable, eco-friendly wood with smooth, rounded edges, it ensures safety during play. It is suitable for children aged 6 months to 6 years and can be used as a climber, bridge, or rocker. Its simple, natural design blends well in any playroom or preschool, encouraging active, imaginative play.

The Indoor Montessori Gym is designed to foster physical and cognitive development in young children. Made from safe, durable wood, it features various climbing, hanging, and balancing elements to promote motor skills and independence. Its versatile design encourages creative, open-ended play for children aged 6 months to 6 years. The gym blends seamlessly into any home or classroom, supporting a Montessori approach to learning through active, hands-on exploration.

The Jungle Gym Set is a dynamic play system that boosts children’s strength, coordination, and confidence. Made from sturdy, weather-resistant materials, it’s ideal for indoor and outdoor use. Featuring climbing ladders, monkey bars, and slides, it supports active, full-body movement. Perfect for ages 3 and up, this set encourages social play, exploration, and physical development in any preschool or backyard environment.

The All-in-One Climbing Frame combines multiple play features, including climbing, sliding, and balancing, to promote physical development in children. Made from durable, child-safe materials, it’s designed for long-lasting use. Suitable for children ages 1 to 6, it encourages motor skills, coordination, and independent play. Its compact and versatile design makes it perfect for indoor and outdoor environments, providing endless opportunities for active exploration and fun.

Why Wooden Climbers Are a Worthwhile Investment for Schools?

When it comes to enhancing children’s learning and play experiences, schools are always looking for equipment that offers long-term value. Wooden climbers have proven to be a valuable investment for their educational benefits and durability, versatility, and positive impact on the overall school environment.

Long-Term Durability and Cost-Effectiveness

When schools choose to make wooden climber structures, they are investing in equipment built to last. Unlike plastic or metal alternatives that may crack, warp, or corrode over time, high-quality wooden climbers are designed to endure years of active use in both indoor and outdoor settings. Wood’s solid construction and natural resilience make it especially suited for educational environments where durability is critical.

Factories that make wooden climber systems for institutional use typically apply advanced joinery techniques, reinforced frames, and protective coatings to enhance structural integrity. This ensures that the climbers remain stable and safe even after extended exposure to environmental elements and repeated daily use by energetic children.

While the initial cost of wooden climbers may be higher than cheaper plastic models, their long service life and low maintenance requirements make them a more economical choice in the long run. Schools that make wooden climber investments can expect reduced repair expenses, fewer replacements, and a higher return on investment—making it a smart, sustainable decision for any educational facility.

Versatility in Design and Use

One key advantage for schools that choose to make wooden climber equipment is the remarkable versatility these structures offer. Wooden climbers can be custom-designed to suit various age groups, educational approaches, and physical environments—whether it’s a spacious outdoor playground or a compact indoor activity room.

When schools decide to make wooden climber systems tailored to their needs, they can integrate features like climbing ramps, tunnels, platforms, balance beams, or interactive panels. This flexibility allows educators to create dynamic play spaces that align with curriculum goals, such as promoting physical literacy, social collaboration, or independent exploration.

Moreover, schools can choose modular designs that evolve with children’s growth and developmental stages. By investing in the ability to make wooden climber structures that adapt over time, institutions gain a long-lasting solution that continues to serve educational and recreational purposes for years. This adaptability makes wooden climbers not just play equipment, but a multifunctional asset in any learning environment.

Enhancing the Educational Environment

In an era where sustainability is becoming a top priority for educational institutions, choosing to make wooden climber equipment reflects a school’s commitment to environmental responsibility. Unlike plastic or metal alternatives, wooden climbers are typically made from FSC-certified, responsibly sourced timber, ensuring that the materials used come from renewable forests and sustainable practices.

When schools make wooden climber structures using eco-friendly materials and finishes, they reduce their carbon footprint and promote greener practices within the learning environment. Additionally, wooden climbers are biodegradable and recyclable, making them a lower-impact choice throughout their lifecycle. Even the production process—especially in modern factories—can incorporate waste-reduction measures, such as reusing wood offcuts or using water-based, non-toxic finishes.

For schools that teach children the importance of protecting the planet, the decision to make wooden climber systems from sustainable resources reinforces those values through everyday play. It also sets a positive example for students, showing that building engaging, high-quality learning environments is possible while caring for the world they’ll inherit.

FAQs

1. Why should schools make wooden climber equipment instead of buying plastic alternatives?

Wooden climbers offer superior durability, safety, and long-term value compared to plastic models. When schools make wooden climber structures using quality materials, they invest in equipment that can last for years, withstand heavy daily use, and provide children with a more natural and engaging play experience.

2. Can we make wooden climber designs that align with specific teaching philosophies like Montessori or Reggio Emilia?

Yes, one of the key advantages when you make wooden climber systems through a professional manufacturer is design flexibility. Structures can be customized to support open-ended exploration, independent learning, and collaborative play, making them ideal for various educational approaches.

3. How can making wooden climber structures support sustainability goals in schools?

Schools that make wooden climber equipment with FSC-certified wood and water-based finishes promote eco-conscious choices. These structures are biodegradable and recyclable and reflect a commitment to environmental stewardship.

4. Can schools make wooden climber for both indoor and outdoor use?

Absolutely. You can make wooden climber units specifically designed for different environments. Outdoor models include UV- and moisture-resistant coatings, while indoor versions may focus more on space efficiency and multi-functionality.

5. How customizable are the features when we make wooden climber equipment for a school?

When you make wooden climber, nearly every aspect—from height, structure, and layout to color and branding—can be tailored to your space and student age group. Schools can even include sensory panels, ramps, tunnels, or integrated storage features.

6. How can we ensure quality control when we make wooden climber equipment in bulk for schools?

To maintain consistent quality, it’s essential to make wooden climber products through factories that follow standardized production processes. Look for suppliers who offer CNC precision cutting, in-house pre-assembly checks, and multiple stages of quality control—from raw material inspection to final packaging. This ensures every unit meets safety and performance expectations, even at scale.

Conclusion

From precision CNC cutting and structural reinforcement to child-safe finishes and sustainability-focused materials, every step in the manufacturing process contributes to a functional and inspiring product. Schools can make wooden climber systems that are fully customized to align with their teaching philosophies, space limitations, and even branding requirements, whether for Montessori, Reggio Emilia, or inclusive learning environments.

Moreover, the decision to make wooden climber equipment reflects a school’s broader commitment to safety, quality, and environmental responsibility. These climbers are built to last, require minimal maintenance, and offer flexibility in design, making them an innovative and future-proof investment. In essence, to make wooden climber equipment is to provide children with more than just a playground—it’s to offer them a thoughtfully designed tool for lifelong learning, movement, and joy.